Race Car Stabilization – Team StarCraft at the Formula Student Germany

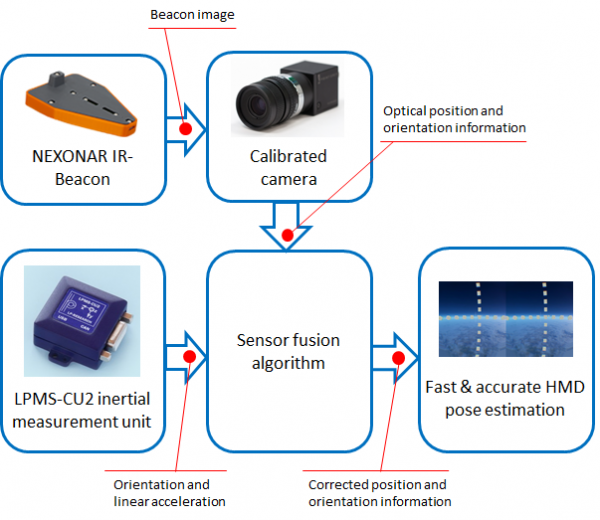

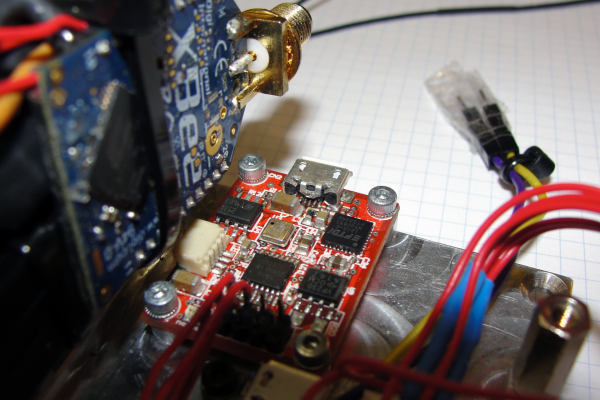

From August 8-14 Team StarCraft of German Technische Universität Ilmenau participated at the Formula Student Germany – International Design Competition. Among many other teams from around the world they took on various challenges including acceleration and endurance races. Sensors such as the IMU (inertial measurement unit) from LP-RESEARCH offered valuable data about air pressure, vertical acceleration and magnetic field strength, which the racing team needed to regulate their traction control in order to perform well. The students used our LPMS-CU to control the car’s Torque Vectoring and the Anti-slip Regulation (ASR).

For next year’s race they will be back with an even more refined car!