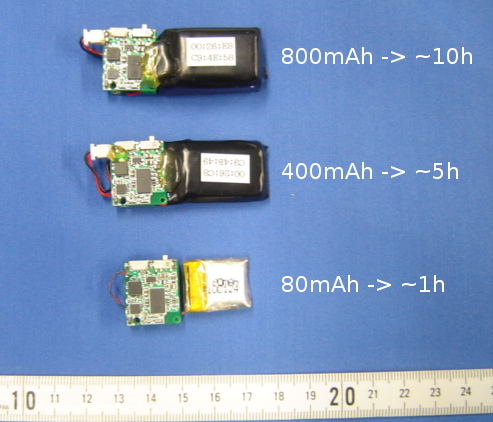

So far we used quite a small battery (80 mAh) to power the LPMS. This worked quite well for some time, but in the end we realized that continuous runtimes of about 1h are just not enough to do practical measurements. We therefore started experimenting with batteries with higher capacity. As you can see in the image below, we were able to prolong runtimes quite a bit, with luckily not having to compromise on size and weight of the sensor too much.

We are not quite ready release the complete specifications of these new types, but basically they will be energy optimized also on the software side and the battery will be exchangeable, so that the user can decide which size he prefers. Also for longer measurements, it might be handy to have a few spare batteries. We will sell additional batteries separately at a decent price.